If you’re a devout DIYer or pro contractor — you need to grasp reciprocating saw uses and how to wield one of these multi-purpose beasts.

While primarily a demolition and salvaging machine, they’re also excellent as all-around home improvement cutting tools — allowing you to shear pipework, trim drywall, and fashion baseboards.

This How to Use a Reciprocating Saw and Its Uses article explains step-by-step the correct method for its safe and rewarding operation — and details the plethora of trade and DIY projects these mighty machines can tackle.

What Is a Reciprocating Saw?

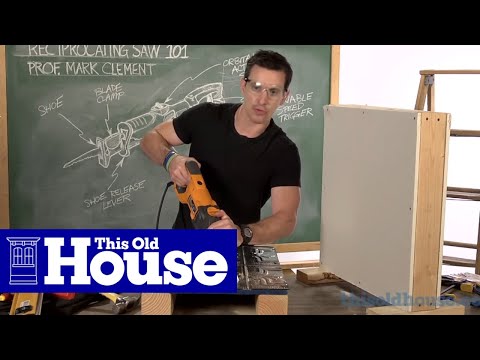

Also known as a recip, hognose, or Sawzall — the reciprocating saw is a handheld electric cutting tool that features a blade that moves in a back and forth motion. Focusing mainly on demolition projects, it can slice through embedded nails and screws, piping, plasterboard, and ply.

For a complete guide to the working processes behind recips — and how they compare to other sawing tools — check out my What Is a Reciprocating Saw 101.

Uses For a Reciprocating Saw

If you’re wondering what are reciprocating saws used for — you’re not alone. Despite being invented back in 1951, these machines haven’t received the same celebrity status as jigsaws, circular saws, or chainsaws. Thus meaning that outside of the contractor arena, many home improvers and DIYers have no comprehension of their versatility.

So, to credit these unsung heroes with the praise they rightly deserve, below is my non-exhaustive list of reciprocating saw or Sawzall uses:

- Demolition.

- Salvaging wood and metal.

- Cutting pipes

- Trimming baseboards.

- Shaping drywall.

- Metal reinforcement cutting.

- Removing/flushing old screws and nails.

- Pruning trees and shrubs.

- Building frames.

- Shortening chain link.

- Shearing sill plates.

- Removing wall slats and floorboards.

- Plumbing.

Reciprocating Saw Safety

Before we get down into the details about how to use a Sawzall or reciprocating saw — a quick word about hazard-free operation.

While generally safe, even for the recip newbie, you’re still wielding a fast-moving and sharp blade. It can make light work of slicing through steel rods — so it isn’t going to break a sweat plowing through your fingers.

Here’s my quick Safe Use Reciprocating Saw Guide:

- If you’re attacking walls, floors, or ceilings — check the area is free from pipes and wiring.

- Always disconnect your recip from the mains when adding accessories or switching blades.

- Don safety gear before commencing cutting — without fail.

- Recips are notorious for ‘kickback’ — keep this in mind, especially when working at high levels or on a ladder.

- After cutting, don’t touch the blade — it will be remarkably hot.

- Never point the blade at yourself or others.

- Don’t wear loose-fitting clothing to avoid them becoming caught in the recip blade.

- Wherever possible, always use two hands to hold the reciprocating saw.

Using Reciprocating Saw — The Equipment You Need

Prior to commencing your cutting project — prepare!

Having the correct tools and equipment readily at hand saves time, prevents work interruption, and adds safety.

While requirements vary from job to job, generally speaking, you need the following:

- A reciprocating saw.

- Extension cable with circuit breaker.

- Straightedge or curve template.

- Carpenter’s pencil.

- Protective equipment — goggles, face mask, gloves, and ear defenders.

- Blades suitable for your target material.

- Water and sponge to dampen down dust.

- Workbench, vice, or clamps for smaller mediums.

- Dustpan and brush for post-project clean-up.

- A cold beer in the fridge as a reward for your hard work.

Using a Reciprocating Saw — Step By Step Guide

You’ve waited long enough! Time to get out your reciprocating saw and get down to some serious cutting.

Step 1- Preparing to Use a Reciprocating Saw

- Disconnect the cell if using a cordless reciprocating saw, or unplug from the mains for a corded unit.

- Select a blade designed for your target medium — retailers have suitable cutting edges for wood, metal, nails, ceramic, and wet timber. Ideally, it should be two to three inches longer than the depth of your base material.

- With reference to the manufacturer’s instruction guide for your particular reciprocal saw, install the blade. Usually, this involves pressing down on the chuck, which releases the internal clamps.

- Slide the blade into the chuck while wearing protective gloves — the teeth of the blade should face downwards. When in place, release the chuck which enables the clamps to grasp the cutter.

- Carefully pull on the blade to ensure that it is secure.

- Adjust the shoe — the protective cage that surrounds the blade. Again, check your instruction manual for the correct method, as this varies from model to model. You’re positioning the shoe to select the correct cutting depth for your project.

Step 2- Preparing Your Work Area

- Using a straight-edge or curved-edge and a carpenter’s pencil — mark the area you wish to address with your reciprocal saw.

- If your target is relatively small and portable, secure it in a clamp, vice, or workbench.

- Put on your protective clothing.

Step 3 – Cutting With a Reciprocal Saw

- Reattach the cordless battery pack or plug into a mains outlet.

- Grasp the recip firmly with both hands — using your dominant hand to grip the handle, and your other hand to support the machine behind the blade guard. This elevates stability and shields against hazardous use.

- Position the shoe against your target medium with the cutting edge of the blade slightly above the starting end of your pencil line — not touching it. Utilize a significant amount of pressure on the shoe to secure your saw and inhibit the risk of kickback.

- When you’re comfortable and ready to cut — gently squeeze the trigger throttle until it reaches the desired speed. If your machine has a variable rapidity dial — ensure it’s set at the correct velocity to suit your medium.

- Address the end of your pencil line to begin penetration of the target material. Keep pushing or forcing to a minimum — allow the recip itself to do the majority of the work. At all times, keep the shoe pressed against your medium, and ensure that the blade isn’t bent.

- If you’re making a plunge cut — that is, in the middle of a piece of material and not the edge — begin the penetration at 45 degrees and repeat with gentle strokes. When the cut is sufficiently deep to accommodate 0.375-inches of the blade — hold the saw in one position and allow it to penetrate through your medium.

- Once the cut is complete — release the trigger and allow the blade to cease movement before withdrawing the tool. This eliminates the risk of hazardous kickback.

- Remove the battery cell or unplug from the mains to prevent accidental operation.

- Carefully remove the blade and store to shield against damage, blunting, or breakage while not in use.

- Clean your work area, stand back, crack open your beer, and admire your handiwork.

Reciprocating Saw Hacks

The above step-by-step how to use reciprocating saw guide should contain everything you need to know when using your tool for the first time. However, if you want to go one step further and cut like a seasoned professional — here are my trade secrets to become a recipmeister:

Select the Perfect Speed

For dense materials like metal, use a slow speed. When addressing softer mediums — for example, drywall — utilize a faster setting. This increases accuracy, prevents kickback, and shields against damage to the blade.

Use the Correct Blade

Fitting the wrong cutting edge makes your work harder, increases hazards, and can lead to blade or tool damage.

Manufacturers retail a plethora of different cutters for a variety of mediums. Generally speaking, use:

- Fine-tooth for metal pipes, screws, and nails.

- Coarse-tooth for wood and plaster.

- Tungsten-grit for tiles, porcelain, ceramic, and stone.

Cover the Reciprocating Saw Shoe

The shoe is crucial for stable cutting — but as it slides along your medium’s surface, it will have an abrasive action. This can be problematic if it touches areas that will be visible in your finished project.

In order to reduce the friction and avoid damage to the material, cover the shoe with a small piece of pipe insulation foam and use gaffer tape to secure.

Lubricate Your Blade

Reducing friction makes cutting easier work and will extend the life of your blade. Use proprietary blade lubricant on both the teeth and blade sides to ensure effortless operation.

Conclusion

As the supreme demolition, salvaging, and construction power tool — the reciprocating saw is a must for any serious DIYer or trade pro.

Always select the correct blade for your target material, utilize an appropriate speed for the density of your medium, and take it slowly!

I hope you enjoyed this reciprocal saw 101. And, if you have a friend, colleague, or family member who you think would also appreciate this step-by-step instruction for recips — by all means, please share!

That’s it, you now know all the reciprocating saw uses and how to wield these machines — so check out our top recip picks and get cutting!

Reciprocating Saw FAQs

Q: What Does a Reciprocating Saw Do?

A reciprocating saw — also known as a hognose, recip, or Sawzall — features a blade that has a back-and-forth motion. Like an electrical hacksaw, you can use this cutting tool to trim nails, cut pipes, shear drywall, and shape baseboards.

For DIYers and trade contractors, the reciprocating saw is used primarily for demolition and construction projects.

Q: How Does a Reciprocating Saw Work?

Internally, the reciprocating saw has a swashplate that transforms the rotary action of its electrical motor into a linear motion. This, in turn, drives a long thin blade to move in a back and forward — that is, reciprocal — movement.

Typically, you can preset the upper-speed limit via a side-mounted case dial — in addition to controlling the velocity output through a variable rapidity trigger throttle.

Q: What Is a Reciprocating Saw Used For?

Used mainly in the construction and demolition sector, the most common uses for reciprocating saw include:

- Plumbing projects — cutting pipes and shaping work surfaces.

- Salvaging metal and wood.

- Removing or shaping drywall.

- Flushing old nails, bolts, and screws.

- Tree pruning.

- Chain link cutting.

- Shaping drywall.

Q: Can Anyone Use Reciprocating Saw?

Yes! With straightforward trigger throttle operation, even total newbies can use a reciprocating saw. For a complete step-by-step guide, check out my above advice on using one of these versatile machines.

The uses reciprocating saw machines can be utilized for are extensive — including cutting pipes and nails, shaping drywall, and removing plasterboard.

Q: Where Can I Find A Sawzall Guide to Operation?

Manufactured by tool giants Milwaukee and first hitting the market in 1951 as the world’s first reciprocating saw — the name Sawzall has become a generic trademark used to describe any recip or hognose machine.

As such, you can use the above guide as a comprehensive 101 to operating a true, patented Sawzall, or a general reciprocal saw.

Q: Is a Jigsaw and Reciprocating Saw?

Strictly speaking, yes. A jigsaw utilizes a blade that moves up and down in a reciprocal motion — therefore making it a reciprocating saw. However, in trade parlance, they are considered in a separate category.

Typically, a jigsaw is operated with the blade moving vertically, while the reciprocating saw has a horizontal motion. Furthermore, jigs are primarily for fine and accurate work — whereas the recip is a hardcore, rough-and-ready, demolition machine.