A question that baffles even the most experienced of drill enthusiasts — what’s the distinction between the brushless vs brushed motor format?

While these two powerhouse types only vary slightly in their engineering build, for the ardent power tool user, it can make a significant difference to performance, with either type possessing qualities that may or may not suit your project’s requirements.

This brushless versus brushed motor face-off article reveals the secrets behind these two power systems, lifting the veil to expose exactly what you should be looking for in your drill, impact driver, or pedestal machine.

Brushless vs Brushed — The Technical Bit

Before we get down to comparing brushed vs brushless drill power tools, a little grasp of the engineering of the formats is helpful. Don’t worry, it’s short and somewhat interesting.

The Brushed DC Motor

Let me start this brushed vs brushless explanation with some juicy scandal.

Back in 1832, William Sturgeon, a British scientist, invented the world’s first brushless motor. Naturally proud of his invention, he wasn’t shy in letting the world — and indeed his fellow inventors — know about this amazing creation. However, while he excelled at publicizing his eureka-moment contraption, he forgot about the small issue of a patent.

Hence, five years later, in 1837, an entrepreneurial American called Thomas Davenport jumped onto this omission and patented it himself. Therefore gaining the credit for someone else’s invention — much like Thomas Edison, Alexander Graham Bell, and allegedly Steve Jobs.

Anyways, down to the brushed motor itself.

Brushed motors have brushes. Brushless motors don’t.

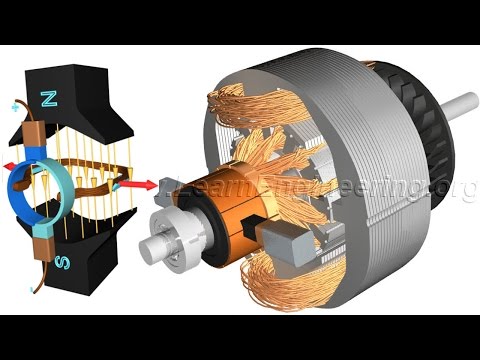

In the center of the brushed motor are wound copper wire coils — typically three — on an armature. As electricity passes through these coils, they create an electromagnetic force. Surrounding this coil (not touching it) are two permanent stator magnets of opposing polarity — indicated by the ‘N’ and ‘S’ on the above image.

Electricity enters the motor via the brushes (shown as graphite brush in the schematic). These brushes touch the commutator, which receives the electrical current and passes the voltage through copper wiring to the internal coils.

The electromagnetic force pushes the core away from the North polarity magnet, making it revolve. As the current is reversed, the South polarity magnet then repels the rotor — now having completed one entire turn. This continual repulsion creates a spinning motion — the basis of every motor.

The factor to bear is this — as the commutator is connected to the rotor, it also spins. However, the brushes (which are touching it, remember) remain stationary. Therefore, these brush contacts are constantly exposed to friction and concomitant heat.

Prefer a visual explanation of a brushed motor in this brush motor vs brushless motor

article? Then check out the video below:

The Brushless DC Motor

While early formats existed in the 19th century, they were massive — you’d be unlikely to fit one in your living room, never mind your drill. It wasn’t until the development of solid-state electronics in the 1960s — diodes, capacitors, transistors, etc. — that these brushless motors became practical.

So, what is a brushless motor?

Like their brushed siblings, the BLDC motors use the identical principle of electromagnetic repulsion and attraction — but their internal construction is different, as demonstrated by the diagram above.

Instead of the commutator and its touching brushes (remember them?), the magnetic stator is turned by using electronic commutation. Confused?

Here’s the process in simple terms. In the brushed motor, the permanent magnets are fixed — the electromagnetic coil rotates inside these stationary components. However, as illustrated in the above image, in a brushless motor the electromagnetic coils are fixed, while the permanent magnets turn.

Here’s the key.

Since the coils are unmoving, there’s no requirement for brushes to deliver electricity around a rotating stator. Hence, they’re brushless.

If you’re still a little befuddled about BLDC’s in this brushless vs non brushless explanation, check out this video:

What Is Better Brushed or Brushless Motors?

Time for the important questions in this brushless motor vs brushed motor battle — what is the ultimate format?

The answer is, perhaps boringly, it depends. Well, generally speaking anyway, as in the drill section below, the relative value of each format is a little more clearly defined.

The Pros and Cons of Brushed Motors

Your house is already full of brushed motors — they’re in kid’s toys, hairdryer, cooling fan, whisk, paint sprayer, electric screwdriver, vacuum cleaner, heat gun, washing machine, and electric toothbrush.

The reason for this proliferation is twofold — affordability and reliability.

Few internal components and mass production mean that you can pick up an electric brushed motor for next to nothing — a standard three-volt unit can typically be obtained for less than a dollar. And, cheaper components mean a more affordable home appliance. So, in a brushless motor vs brush motor cost battle — the brushed version wins.

However, expose them to any pressure, and they begin to fail — hence the requirement for brushless motors.

The Pros and Cons of Brushless Motors

Under high force, brushed motors are vulnerable to substantial heat and friction — as the brushes are in constant contact with the turning rotor. This rapidly wears away at the contacts and commutator, increasing the likelihood of failure.

Additionally, these significant temperatures are transferred to the rest of the motor and machine, damaging the internal components and making the outer casing excessively hot.

The beauty of brushless motors is this heat and friction are seriously reduced. With no brushes continually touching the fast-turning rotor, these powerhouses remain relatively cool, extending the lifespan of the unit.

Furthermore, as no energy is lost to resistance and heat, the motor is more efficient than its brushed sibling. Hence, two motors drawing an equal voltage, the brushless format will deliver greater speed and torque than the less efficient brushed unit.

I know what you’re thinking, if brushless motors are this impressive, why aren’t they in every household appliance?

The reasons are cost and maintenance.

Brushless motors are tech-packed, their high reliance on solid-state electronics makes them significantly harder on the wallet than brushed — therefore raising the price of the final products.

Additionally, while their low-friction operation makes them less liable to failure — if they do break down, they’re costly to repair. While any semi-experienced DIYer can replace brushes or coils on a brushed motor, you need some serious in-depth knowledge to self-repair an electronic-heavy brushless unit.

Brush vs Brushless Drills

So, are brushless drills better? Undoubtedly, yes!

The advantages of using brushless drill include:

Low Maintenance

With no brushes to wear out, nor components being exposed to high heat, brushless drills have a seriously long lifespan. It’s much more likely that the chuck bearings will degrade long before the motor fails.

Take, for example, the mighty DeWalt DCD708C2. This cordless drill driver is built for hardcore day-to-day trade use, yet has reviews testifying to the fact that it rarely fails.

Low Vibration

The low friction of a brushless drill’s motor reduces oscillation in the casing and handle. This leads to a more pleasant operating experience, elevated accuracy, and a reduced chance of fatigue curtailing your project.

This is even more crucial when using a hammer or rotary drill — where the constant pounding of stubborn concrete can be tough on the hands or arms. The Makita XPH07Z is an excellent example of a grunty brushless hammer unit that’s low on the vibration scale.

High Efficiency

It’s in the efficiency category that the question is brushless better than brushed the easiest to answer. Yes!

Due to little energy waste through friction and heat, you enjoy more power and torque from a brushless drill than you will from a brushed drill with a comparable motor. And while this is beneficial for grunt output in corded tools, it’s in the battery-driven arena that brushless models excel.

Their high efficiency means less draw on the lithium-ion cell that powers the drill, resulting in longer running times — up to 50 percent — than their brushed cousins. This permits you to work for extended periods of time from a single charge — meaning less downtime replacing cells or waiting for the battery to recharge.

For example, the brushless DeWalt DCD996B promises around 45-50 minutes of continual operation from a single charge.

In addition to the above three areas, the brushless vs non brushless drill battle demonstrates that the brushless variety has the edge due to:

- Greater torque to weight ratio.

- Lower noise.

- No risk of sparking ionization emitted from the commutator.

- Virtual obliteration of EMI (electromagnetic interference).

Drill Brushless vs Brushed — Should Brushed Drills Be Avoided?

In reading the above brushless drill vs non brushless advantages — it’s a natural assumption that the brushed models are inferior and not worthy of consideration.

That is a mistake.

Sure, when comparing brushless drill vs brushed drills, the former has the advantage on weight, efficiency, low maintenance, and low vibration. However, a Ferrari is better than a Ford — but chances are you haven’t got an Italian prancing horse on your driveway.

When selecting between a brush or brushless drill, it’s crucial that you consider you and your project’s demands and requirements.

Firstly, weigh up the cost differential. Depending on the make and model, brushless units can be anywhere from 25-50 percent harder on the wallet than their brushed counterparts.

Secondly, think about the efficiency when choosing between a brushless vs brushed drill. If your heart is set on a cordless machine and you need long-running times, then it’s a no-brainer — go for a brushless unit.

However, if you want a corded drill, or don’t expect to be drilling for longer than 20-30 minutes with a battery-driven tool — the efficiency disparity will be negligible for your needs. Just opt for a quality brushed unit such as the mains-driven DeWalt DW511 or the cordless Makita XFD10Z.

Finally, consider your level of usage when deciding between a drill brush vs brushless model. Sure, brushless models have greater durability, but this only becomes a crucial factor if you’re using the tool on a frequent basis. If you don’t anticipate switching on the drill more than once a month, the reliability of a brushless unit is unimportant.

Brushed vs Brushless Tools Conclusion

Deciding between a brushless motor vs brushed motor drill is a vital consideration when purchasing a new boring tool.

The brushless models are the kings of the two categories, delivering greater efficiency, power, reliability, and running times on cordless machines. However, they are at a higher price tag, offer less user maintenance, and have negligible energy efficiency on corded tools.

Your perfect drill depends on the demands of your project, your budget, and your level of use.

I hope you found this brushless vs brushed motor article informative and interesting — if you have a buddy that would enjoy reading this 101, please feel free to share!

Brushless Motor vs Brushed FAQs

Q: What Does Brushless Mean?

Brushless refers to motors that utilize rotating permanent magnets inside fixed coil electromagnets. This eliminates the requirement for brushes that typically deliver electricity to the commutator.

Q: DeWalt Brushless Drill vs Brushed DeWalt Drill?

A brushless DeWalt drill, such as the cordless DCD996B, offers lengthy running times due to its high-efficiency motor. The reliable mains-driven DeWalt DW511 has a brushed motor, but being corded, the issue of energy efficiency is less significant.

Q: Are Brushless Drills Better?

When choosing between brushless drill vs brushed drill, the question of whether the brushless version is better depends on your requirements. Brushless models offer high efficiency and reliability, although they’re significantly harder on the wallet than their brushed cousins.

Q: What Is a Brushless Drill?

A brushless motor drill negates the requirement for friction and heat-causing brushes to deliver electricity to the commutator. Instead, they utilize a system of rotating permanent magnets inside stationary electromagnets.

Q: Are Brushless Tools Better?

The difference between brushless drill and brushed drill — or indeed a brushless vs brushed impact driver — is mainly efficiency. Low on heat and friction, they deliver higher speed and torque outputs than their brushed siblings from an identical power source.

Q: Are Brushless Motors Better?

Due to brushless motors experiencing lower heat and friction than brushed examples, they offer higher reliability and greater efficiency.